News

Press Releases of Kelheim Fibres GmbH.

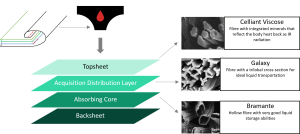

At Techtextil, taking place in Frankfurt at the end of April 2024, companies Kelheim Fibres and Gebr. Otto will showcase their joint concept aimed at making period underwear more sustainable and high-performing. Exhibiting at the BW-i joint stand and the IVGT joint stand, both located in Hall 12.1, the innovation partners will present their solution for period underwear made from biobased materials, distinguished by outstanding performance metrics. The various specialty viscose fibres used in this solution are sourced from Kelheim, while Gebr. Otto expertly spins them into the appropriate compositions.

On average, a woman consumes about 15,000 hygiene products in her lifetime, primarily disposable items that generate significant waste. Their plastic components take up to 500 years to decompose, breaking down into smaller and smaller pieces over time. The trend toward making female hygiene products, both disposable and reusable, more sustainable has been growing in recent years. This category includes not only biodegradable disposables but also washable period panties offered by established lingerie manufacturers and innovative startups.

Enhancing sustainability and performance of reusable products

This is where fibre manufacturer Kelheim Fibres and yarn spinner Gebr. Otto step in, aiming to make period underwear as comfortable, high-performing, and sustainable as possible. The solution is akin to solving a puzzle, considering that period underwear is constructed from multiple layers with different functions. For instance, the topsheet must quickly absorb and divert liquid away from the body, while the subsequent acquisition-distribution layer (ADL) ensures rapid and optimal distribution of the liquid within the absorbent core, which then encapsulates the liquid, preventing potential leakage.

Pooling expertise

With the optimal combination of Kelheim’s specialty fibres and Otto’s perfectly matched yarn types, the two innovation partners have solved this puzzle. The result is a prototype that outperforms conventional solutions in terms of liquid absorption speed, capacity, and rewet values. “Based on the requirements and test results Kelheim has determined for the various layers, we develop our yarn blends,” explains Andreas Merkel, Managing Director of Gebr. Otto. “We can promptly supply the desired yarns for short-term requests, including special inquiries from lingerie brands.”

Inherently sustainable

The collaborative innovation between Kelheim Fibres and Gebr. Otto is a significant gain for the sustainability of period underwear. Not only do both companies utilize efficient state-of-the-art technology, but Kelheim’s biobased viscose fibres also contribute to the eco-friendliness of the product. Moreover, the partnership between these two German traditional companies enables an exceptionally short supply chain. Dr. Marina Crnoja-Cosic, Director of New Business Development at Kelheim Fibres, emphasizes: “Short supply chains are not only environmentally friendly but also crucial for compliance with supply chain laws and product responsibility. Regional partnerships like the one with Gebr. Otto ensure that our supply chain is transparent and efficient, ultimately leading to a more sustainable future.”

Kelheim Fibres, a leading manufacturer of viscose specialty fibres, is showcasing recent research findings at this year’s Cellulose Fibres Conference. The development, led by Dr. Ingo Bernt, Project Leader of Fibre & Application Development at Kelheim Fibres, and Dr. Thomas Harter from Graz University of Technology, provides insightful insights into the correlation between the geometry of viscose fibres and the liquid absorption of tampons.

Kelheim Fibres has long been engaged in the functionalization of viscose fibres, including the specific adaptation of fibre cross-sections.

The trilobal Galaxy®, highly esteemed in the industry as THE tampon fibre from Kelheim Fibres for many decades, serves as a prime example. The current study now underscores the unique properties of the fibre, primarily rooted in its geometry. This involves taking a closer look at the underlying mechanisms.

It has been confirmed that, in contrast to the traditionally round viscose fibres and despite similar chemical compositions and mechanical properties, Galaxy® enables significantly better liquid absorption: While the higher specific surface area of trilobal fibres already promotes improved liquid absorption, this is not the main factor accounting for the difference in absorption. Instead, the geometric shape of the fibres proves to be crucial. Trilobal fibres create and maintain a more voluminous, extensive network within the absorbent body, providing a larger volume for liquid absorption.

Dr. Ingo Bernt emphasizes, “The results of our study are not limited to tampons—any application requiring increased absorbency can benefit from the properties of our Galaxy® fibres.”

For more information, join the Cellulose Fibres Conference on March 14th in Cologne, where Dr. Ingo Bernt and Dr. Thomas Harter will present the lecture “Geometry Matters: Unveiling Tampon Absorption Mechanisms” at 2:50 PM.

Kelheim Fibres GmbH, leading manufacturer of specialty viscose fibres, has announced to increase its prices by 12% to 15% for specialty viscose fibres starting April 1, 2024.

With the strong rebound in cotton fibre prices, there has been a sharp increase in the demand for viscose, especially in Asia. In the face of the rapid rise in interest rates, wages, chemicals, and environmental costs, accompanied by depressed fibre prices over the past years, Kelheim Fibres has no other choice than to start improving margins back to sustainable levels by raising the base price.

Kelheim Fibres GmbH, leading manufacturer of specialty viscose fibres, and the Italian textile machinery manufacturer, Santoni Spa, were honored with the ITMF International Cooperation Award 2023 during the ITMF Annual Conference in Keqiao, China. This prestigious recognition by the International Textile Manufacturers Federation (ITMF) acknowledges outstanding achievements in international collaboration within the textile industry in alignment with the values of the 17 Sustainable Development Goals (SDGs) of the 2030 Agenda for Sustainable Development.

Together, Kelheim Fibres and Santoni have developed an innovative and sustainable period panty, built upon advanced machine technology and high-performance viscose fibres. The result is a sustainable and high-performance underwear garment that seamlessly combines comfort and functionality.

Santoni’s specialized machinery enables a significant reduction in fabric waste, or even the potential for entirely waste-free production. Simultaneously, it enhances production efficiency, leading to cost savings. Kelheim Fibres’ wood-based specialty fibres, such as the trilobal Galaxy® and the hollow Bramante fibre, replace synthetic materials in the absorbent core of the menstrual underwear. They offer excellent performance and reliable protection for the wearer.

Natalie Wunder, Project Manager for New Business Development at Kelheim Fibres: “At Kelheim Fibres, we are dedicated to the open innovation approach. Collaborating with our partners across the value chain, we craft innovations that draw the best from all sources. This partnership not only consolidates expertise but also accelerates the entire innovation process. As a result, we ensure that our developments align with market needs and deliver sustainable solutions. With our project in collaboration with Santoni, we have achieved a new level in the domain of sustainable menstrual underwear. We take pride in the ITMF honouring our achievements with the International Cooperation Award, which serves as recognition of our work and inspiration for future collaborations.”

ITMF Award Ceremony

From left to right: Mr. Ruizhe Sun, CNTAC President and former ITMF President; Patrick Silva Szatkowski, Santoni S.p.A., Betty Wu, Kelheim Fibres; Mr. Juan Parés, Textil Santanderina Spain, Jury Member and Vice President ITMF; Dr. Christian Schindler, ITMF Director General;

© ITMF

Kelheim Fibres, a leading manufacturer of specialty viscose fibres, showcases its latest developments at this year’s Global Fiber Congress in Dornbirn. The focus is on innovative solutions that not only promote environmental sustainability but also strengthen the European supply chain.

In his presentation “Towards high performing plant-based AHP products – a joined approach of Pelz and Kelheim Fibres,” Dr. Ingo Bernt, Project Leader of Fiber & Application Development at Kelheim Fibres, together with Dr. Henning Röttger, Head of Business Development at PelzGROUP, introduces the development of a plastic-free yet high-performance panty liner. The water-repellent Kelheim specialty fibre Olea plays a crucial role in both the top and backsheet of the panty liner. This product emerged from the ambition to offer eco-friendly alternatives to conventional disposable hygiene solutions without compromising on product performance.

A similar approach is pursued in the second presented project – but Kelheim Fibres takes it even further. Under the title “Performance Fibres meet Sustainable Design – example of a reusable Baby Diaper,” Natalie Wunder, Project Leader from Kelheim Fibres’ New Business Development team, together with Caspar Böhme, Co-Founder of Sumo, introduce the washable and reusable SUMO diaper. Made from biobased materials and featuring a unique construction with Kelheim specialty fibres, this combination offers double environmental benefits compared to conventional disposable baby diapers.

Both the panty liner and the SUMO diaper are manufactured entirely in Europe, resulting in shorter transportation routes and a reduced CO2 footprint. Moreover, these innovations contribute to strengthening the European textile and nonwovens industries by fostering innovation within Europe.

Meet Kelheim Fibres at the Global Fiber Congress in Dornbirn and discover more about the company’s groundbreaking innovations.

The viscose specialty fibre manufacturer Kelheim Fibres has entered into a collaboration with MagnoLab, an international network of companies in the textile industry based in the Biella region. This partnership highlights the importance of collaboration between different companies to drive innovation and sustainability in the textile industry. Kelheim Fibres, a pioneer in the development of sustainable viscose fibres, sees itself not only as a fibre supplier but also as an innovation partner for the entire industry. Through its Open Innovation approach, Kelheim Fibres fosters the exchange of ideas and knowledge to jointly develop sustainable solutions for the future.

Kelheim Fibres operates several pilot and technical facilities itself. The close collaboration with MagnoLab, which boasts an impressive array of state-of-the-art textile machinery, allows for even more efficient research and development.

Dr. Marina Crnoja-Cosic, Director New Business Development, Marketing & Communications at Kelheim Fibres, emphasizes the advantages of the collaboration: ” Through close networking with the companies organized under MagnoLab, we can produce small quantities of samples and prototypes using various technologies. This enables us to develop solutions based on our specialty fibres that can be directly transferred to our partners’ production facilities within the textile value chain.”

Giovanni Marchi, President of MagnoLab, also expresses his enthusiasm: “Kelheim Fibres is the first fibre manufacturer we are collaborating with. Together, we now cover the complete textile chain, making our work even more valuable.”

The cooperation allows for practical testing, accelerating the implementation of innovations. It also contributes to a closer networking of the European (and thus regional) value chain. Thanks to shorter transport routes within Europe, not only is the environmental impact reduced, but also the realization of innovations in Europe is facilitated.

After nearly 30 years with the company, Matthew North, Commercial Director at renowned viscose specialty fibre manufacturer Kelheim Fibres, will retire on July 1, 2023. Throughout his long and successful career, he has played a significant role in transforming Kelheim Fibres from a supplier of standard fibres to the European textile industry into a supplier of predominantly customized specialty fibres for the hygiene, specialty paper, and textile industries.

Craig Barker, CEO of Kelheim Fibres, said, “On behalf of the entire team, I would like to express our gratitude to Matthew for his outstanding work over the past decades. His wealth of experience, calm nature, and British humor will be greatly missed. We wish him all the best for his exciting new chapter in life. At the same time, we wish Mark von der Becke and Dr. Marina Crnoja-Cosic much success in the new responsibilities they have now assumed.”

From left to right: Mark von der Becke, Dr. Marina Crnoja-Cosic, Matthew North

Mark von der Becke will assume the position of Sales Director and become part of the management team at Kelheim Fibres. The 48-year-old brings extensive experience in sales, marketing, and key account management. He has held various leadership positions in renowned companies such as Hoechst, Clariant, and DS Smith in Germany, Switzerland, and China. He is known for successfully developing and implementing strategy and change programs.

Dr. Marina Crnoja-Cosic, who has been serving as Director of New Business Development and a member of the management team at Kelheim Fibres since 2020, will take on the responsibility for marketing and communications. She has already proven herself as a dedicated and competent leader and will now drive the further development of the marketing strategy and communication with customers and partners.

Kelheim Fibres GmbH and Santoni Spa have jointly developed an innovative and sustainable menstrual underwear garment based on advanced machine technology and high-quality performance viscose fibres. The product consists of a soft outer layer and an inlay made from special wood-based fibres from Kelheim. The result is a sustainable and high-performance product that combines comfort and functionality.

The soft outer layer is produced on Santoni SM8-TOP2V circular knitting machine or on the SM4-TL2 machine. One of the major advantages of these circular knitting machines is that they significantly reduce the amount of cutting waste or even allow production with zero-waste.

The Santoni XT-Machine, originally developed for the footwear market, is used for the functional inlay of the period panty. The unique XT-Machine allows for different layers to be produced with different yarns and knitting structures. This enables all three functions of the inlay – the absorption and distribution layer ADL, the absorbent core, and the back layer – to be knitted in a single tube. This reduces production time and costs and enables zero-waste production.

In the inlay, wood based Kelheim specialty fibres such as trilobal Galaxy® or the hollow Bramante fibre replace synthetic materials.

Santoni and Kelheim Fibres both stand for tradition as well as sustainability and innovation. Patrick Silva Szatkowski, Marketing Manager at Santoni, is pleased with the collaboration: “Our machines have changed the manufacturing process, making garments almost seam free and offering solutions for 3D knitting. Our goal is to provide efficient machineries to produce sustainable and comfortable garments while reducing the quantity of operations. The collaboration with Kelheim Fibres GmbH has been driven by the same values and we are proud of the excellent result”.

Natalie Wunder, Project Manager New Business Development at Kelheim Fibres, emphasizes: ” With this joint development and the combination of our different areas of expertise we have expanded our range of femcare products. Once again we show how our special viscose fibres play an essential role in performance and sustainability in hygiene products. I look forward to seeing the project commercialized soon – partners are always welcome.”

Viscose speciality fibre manufacturer Kelheim Fibres, nonwoven producer Sandler, and hygiene product manufacturer pelzGROUP have jointly developed a new panty liner that is plastic-free according to the European Single-Use Plastics Directive (SUPD). This innovative solution is a step towards reducing the amount of plastic in hygiene products – and thus also a contribution to tackling the global problem of plastic pollution.

According to a UNEP study on marine litter and microplastics, eight million tons of plastic end up in the oceans every year. A significant portion of this pollution comes from single-use plastic products, including conventional period products such as pads or panty liners. The need for sustainable alternatives has never been greater, and this collaboration between Kelheim Fibres, Sandler, and Pelz is a much-needed step in the right direction.

The partnership between the three companies was formed under the Open Innovation principle, which allowed for creative idea exchange and facilitated the development of a truly innovative product.

According to Jessica Zeitler, R&D Specialist at Sandler, “Our collaboration with Kelheim Fibres and pelzGROUP is a great example of how companies can work together to create solutions that benefit both the environment and consumers. We are proud to be part of this project and the opportunities it offers.”

For hygiene product manufacturer pelzGROUP, it is important to combine sustainability and performance to achieve broad acceptance in the market. “Our panty liner meets the strict requirements of the European Single-Use Plastics Directive (SUPD) while also matching the performance of conventional synthetic products. At the same time, our new panty liner has a completely European supply chain. This means short distances and therefore low CO2 emissions, and – especially in times of global disruption – reliability for our customers,” emphasizes Dr. Henning Röttger, Head of Business Development at pelzGROUP.

“Our viscose speciality fibres are an environmentally friendly and high-performance alternative to synthetic materials,” says Dominik Mayer, Project Manager Fibre & Application Development at Kelheim Fibres. “They are at the very beginning of the product value chain and yet have an enormous impact on the functionality of the end product. Open innovation allows us to bring all partners in the value chain to the table, to find the best solution together in a very short time and bring it to commercialisation – the collaboration with Sandler and pelzGROUP is an important milestone in our AHP journey.”

The panty liner will soon be commercially available under the pelzGROUP’s COSMEA brand.

Absorbent hygiene products such as diapers, sanitary pads, and incontinence products are an integral part of our daily lives. However, most of these products contain synthetic components and contribute to the global plastic waste problem. The search for alternatives is becoming increasingly urgent. The catch is that only innovations that offer the same performance and reliability as conventional products can be successful in the market. After all, no one wants to compromise in such a sensitive area as personal hygiene.

Kelheim Fibres is currently working on various development projects to design fully biobased AHP (absorbent hygiene product) concepts that do not compromise on performance. In this area, the company continues to focus on its wood-based specialty fibres, which the tampon industry has trusted for decades. However, the requirements for AHP products differ, as each layer must fulfil a specific function.

To meet these requirements, Kelheim Fibres has developed a range of functionalized specialty fibres, including hydrophobic Olea, trilobal Galaxy®, and the hollow fibre Bramante. These specialty fibres ensure optimal results in every layer of the AHP product.

All of Kelheim’s fibres are manufactured from 100% wood pulp derived from certified and sustainably managed forests. They are fully biodegradable – microorganisms in soil and seawater ensure that no residues remain.

“As pioneers in our industry, we do not limit ourselves to producing innovative fibres,” says Dr. Crnoja-Cosic, Director of New Business Development at Kelheim Fibres. “Together with our partners we develop holistic concepts that cover the entire value chain. Through this collaboration based on the Open Innovation principle, products are created that take into account the real needs of customers and are thought through from beginning to end, so they can be quickly ramped up to a commercial scale.”

A current example of such a partner project is the development of a completely bio-based panty liner with the nonwovens manufacturer Sandler and the hygiene products manufacturer pelzGROUP, which is due to be launched on the market shortly.

In addition to new projects in the field of biobased disposable and reusable solutions, Kelheim will also present its tried and tested fibres at the fair, for example for tampons or flushable wipes. The Kelheim Fibres team is looking forward to your visit at booth 2415 at INDEX.

Kelheim Fibres, the world’s leading manufacturer of viscose speciality fibres, has joined Recycling Atelier Augsburg. Recycling Atelier Augsburg is a unique centre for research and development in the field of textile recycling. It is located at the Institut für Textiltechnik Augsburg an affiliated institute of Augsburg University of Applied Sciences. The two institutions founded the Recycling Atelier in June 2022 together with twelve partners from the German textile industry.

As a model factory, the Recycling Atelier Augsburg combines the most important processes of textile recycling and offers holistic and comprehensive research along the value chain,” explains Georg Stegschuster, head of the Recycling Atelier Augsburg. The scientists research on all process steps of textile recycling: from material analysis to sorting, preparation and textile processing to sustainable product design. Comprehensive data collection and the use of artificial intelligence as well as innovative materials play a central role.

Kelheim Fibres is a producer of high-quality viscose fibres, which consist of cellulose, the main component of the renewable raw material wood, and are used worldwide for products in areas such as hygiene, textiles, and technical applications.

“In New Business Development as well as Fibre and Application Development, we follow the Open Innovation concept – the cooperation with the Recycling Atelier offers us an ideal platform for this. Here we work with partners to advance sustainability and performance,” explains Maik Thiel, project manager at Kelheim Fibres.

Recycled cotton fibres are often very short or of uneven length, which makes further processing of 100 % recycled material a challenge. This is where the speciality fibres from Kelheim Fibres come into play, whose addition should enable the production of high-quality new products, such as nonwovens. In the future, the fibres provided by Kelheim Fibres will also be made from recycled pulp. Closing the loop further.

In the Recycling Atelier, the focus is on the triad of technical and ecological sense as well as economic benefit. In this way, the partners of the Recycling Atelier are standing up against fast fashion, outsourced corporate responsibility and a general decline in raw material quality, which often fuels downcycling – the low-quality reuse – of materials.

Kelheim Fibres and SUMO are presenting their high-performance absorbent pads for the reusable Sumo diaper at this year’s Cellulose Fibres Conference. The Sumo diaper is a sustainable and washable cloth diaper made entirely from biobased materials, offering high performance and innovative design.

The developers of the Sumo diaper recognized that many parents are looking for a healthy and sustainable alternative to synthetic disposable diapers, which create a tremendous amount of plastic waste. The Sumo diaper offers a reusable alternative, consisting of a waterproof shell and absorbent pads. To enhance the performance of the pads, Sumo collaborated with Kelheim Fibres, a leading viscose specialty fibre manufacturer with decades of experience in the hygiene sector.

Together with the Saxon Textile Research Institute STFI, Sumo and Kelheim Fibres have developed a high-performance absorbent pad that is free of fossil-based materials and has already been awarded the Techtextil Innovation Award. The basis for the innovative construction are Kelheim’s functionalized specialty viscose fibres with modified cross-sections, which ensure particularly high absorbency and extremely low rewet values.

To ensure the washability of the product, needle-punched/thermally bonded nonwovens were chosen, consisting of a mixture of specialty viscose and PLA bicomponent fibres. By combining nonwovens, typically used in single-use applications, with reusable products, the partners have chosen a new approach.

Natalie Wunder, project manager at Kelheim Fibres, and Luisa Kahlfeldt, founder and designer of SUMO, explain in their joint presentation at the Cellulose Fibre Conference how open innovation has led to successful development collaboration, how this response to current consumer needs has emerged, and what steps are planned for the future.

The renowned viscose fibre manufacturer Kelheim Fibres welcomes the preliminary political agreement reached between the European Parliament and the Council on an EU regulation on deforestation-free supply chains, which was adopted at the end of 2022. The new rules are intended to prevent goods that cause forest degradation or deforestation from being placed on the EU market.

As one of the largest economies worldwide, the EU is a major consumer of wood-based raw materials. Therefore, the new law can significantly contribute to reducing global deforestation and forest degradation as well as protecting threatened forest areas.

“Wood is an incredibly versatile and valuable renewable resource and the basis for countless products. Our viscose fibres are just one example – they offer an environmentally friendly alternative to synthetic materials in various applications and are thus a promising material for the future. Of course, this only applies if the production of our raw materials does not take place at the expense of our earth’s natural forest resources. These forests are a bastion of biodiversity and climate protection for our entire planet and must be protected at all costs. No one can escape this responsibility,” says Craig Barker, CEO at Kelheim Fibres.

Therefore, Kelheim Fibres has been exclusively using FSC® or PEFCTM certified pulps exclusively from sustainably managed sources for many years and has received a top spot in the HotButton ranking three times in a row. This ranking is compiled annually by the Canadian NGO Canopy that campaigns for the preservation of ancient and endangered forests.

EcoVadis, the world’s largest provider of sustainability ratings for companies, awarded us Gold for the second time in a row. The rating was well above average in all four individual areas (environment, labour and human rights, ethics, sustainable procurement), but Kelheim Fibres achieved absolute top scores in the environment area in particular.

We are very proud to once again be among the top 3% of all companies evaluated and would like to say a big thank you to our entire team for this great achievement!

In this year’s “Hot Button Report” released on November 9, 2022, by environmental NGO Canopy, Kelheim Fibres has once again achieved a top position with a dark green/green shirt and was able to improve its overall ranking by another 1.5 points compared to the previous year.

The Hot Button Report thus confirms the viscose speciality fibre manufacturer’s leadership role when it comes to conserving Ancient and Endangered Forests. For example, Kelheim Fibres has once again increased the proportion of FSC®-certified pulp in its production and confirmed in an audit that its supply chain is low-risk of sourcing from Ancient and Endangered Forests. There was also credit for the active and public support of Canopy’s work, as well as research and development of low impact Next Generation fibre solutions.

And finally, the Bavarians achieve top points in the areas of chemical management and transparency. As a member of the non-profit organisation ZDHC (Zero Discharge of Hazardous Chemicals), Kelheim Fibres supports their goal of completely eliminating harmful substances from the textile value chain. Furthermore, Kelheim Fibres is the only EMAS-validated viscose fibre manufacturer worldwide to regularly publish all relevant environmental data.

“We are proud to have improved again in the Hot Button Report and to be able to hold our own as a relatively small viscose fibre manufacturer among much larger companies,” says Matthew North, Commercial Director at Kelheim Fibres. “Our fibres are an environmentally friendly alternative to synthetic materials – of course, this is only possible because we also live the environmental concept in the sourcing of our raw materials and in all steps of production.”

Viscose speciality fibres manufacturer Kelheim Fibres partners with TextileGenesisTM, an award-winning

traceability platform that createsradical transparency from fibre-to-retail and ensures authenticity d provenance

of sustainable textiles against generics.

“Our wood-based fibres are an environmentally friendly basis for sustainable textiles – it’s just that consumers

often don’t know what’s behind their garments. But they need to know it’s in their hands to minimise the

ecological footprint of the textile industry. Transparency and traceability are the foundation that enables

consumers to make informed decisions.”, says Dr. Marina Crnoja-Cosic, Director New Business Development at

Kelheim Fibres.

TextileGenesisTM uses blockchain technology to track and verify the use of sustainable fibres all the way from

fibre to garment. A digital fibercoin ensures transparency and reliability throughout the entire production line

and beyond.

Amit Gautam, Founder & CEO at TexileGenesisTM:”Fashion and textile value chain is undergoing major

transformation driven by sustainable materials, shifting consumer demand for sustainable products, and

increasingly stringent regulations on transparency. Great to see Kelheim moving the industry forward by actively

participating in the traceability journey”.

Shorter product life cycles and rapid technological progress are changing our product landscape at an ever-faster pace. The ability to anticipate future changes and to proactively shape the change – instead of running to keep up with it – is therefore an increasingly decisive competitive factor for modern companies. Trends are considered to be important indicators of impending change.

Kelheim Fibres, the world’s leading manufacturer of viscose speciality fibres, stands out in the industry not least for its innovative strength, as evidenced by numerous awards such as the Techtextil Innovation Award 2022 in the “New Concept” category. At this year’s Global Fiber Congress Dornbirn, Innovation Manager Ilka Kaczmarek will give an insight into the innovation management of the Bavarian fibre experts in her presentation “Trend Management meets Open Innovation: Best Practice Examples from Kelheim”. Ilka Kaczmarek will show how successful product solutions were developed in a short time by focusing on customer needs and working closely with partners along the value chain.

Natalie Wunder, Project Manager at Kelheim Fibres, will explain one of these examples in detail in her presentation “Development of Menstruation Pants using Speciality Viscose Fibres”. Based on the current trend and the desire of end customers for reusable products, Kelheim Fibres was able to develop a washable and thus reusable, yet bio-based solution for feminine hygiene products.

In addition to the presentations, the Kelheim Fibres team is also looking forward to exchange ideas and inspirations at their information stand at the Dornbirn GFC.

The renowned viscose specialities manufacturer Kelheim Fibres has won the Techtextil Award in the “New Concept” category for their project “Cellulose-based nonwovens for highly absorbent reusable products”.

This award is intended to make cutting-edge developments visible, promote unconventional thinking and intensify the dialogue between researchers, manufacturers, and users – and thus exactly matches the philosophy of the fibre expert.

Dr. Marina Crnoja-Cosic, Director New Business Development at Kelheim Fibres: “It is a great honour and pleasure for us to receive the Techtextil Award. We see the award not only as an acknowledgement for the project presented, but also as a recognition of our innovation strategy. Our open innovation concept aims at dialogue and the associated acceleration of the commercialisation of innovative solutions. In this specific example, it has been shown that together with our partners, the Saxony Textile Research Institute STFI and Sumo, we have been able to react faster and more specifically to current trends. Together we achieved a better result. By joining forces, we have developed a product that optimally combines performance and sustainability.”

The starting point for the innovation was the search for a washable and thus reusable absorbent pad made of completely bio-based materials for the cloth diaper of the Berlin-based start-up Sumo.

Two main requirements of the application are obvious: A fast and efficient liquid distribution and high absorbency should minimise rewetting and leakage. Both are ensured by speciality viscose fibres from Kelheim, which have been making this essential contribution to absorbent hygiene products such as tampons for many years.

The obvious solution was therefore to optimally utilise the synergies between knitted and woven structures with nonwovens.

In doing so, the advantages of nonwovens in combination with speciality viscose fibres in terms of absorbency (through e.g. more open-pored structures) have been perfectly transferred from the field of disposable to the world of reusable products. For reusable products, however, there is another challenge to overcome: they must remain stable during washing and over several cycles of use. To ensure this, an innovative nonwoven construction was developed in close cooperation with the STFI. These nonwovens can be used as a stand-alone solution or integrated into a textile structure.

In the Sumo cloth diaper, the liquid management of the absorbent pad sets new standards. The new solution combines the worlds of nonwovens and textiles and provides proof that high-performance reusable absorbent products can be developed without fossil materials.

From left: Patrick Engel (STFI), Caspar Böhme (Sumo), Ilka Kaczmarek und Dr. Marina Crnoja-Cosic (both KF) at the Techtextil Innovation Award Ceremony

Up to the age of three, a baby uses around 5,000 diapers – and although common disposable diapers score points with their convenient handling, parents are increasingly looking for a healthy and sustainable alternative to these products, which are in most cases synthetic. After all, they cause an enormous amount of plastic waste – in Germany alone, 10 million diapers are disposed of every day.

There are two ways to solve this dilemma: Either disposable products are made from bio-based or biodegradable materials, or reusable products with a longer life span replace disposable products.

Founding team Luisa Kahlfeldt and Caspar Böhme go even further and combine both with their “Sumo Diapers.” They have created a reusable cloth diaper that is made entirely of sustainable materials while offering high performance and innovative design.

The Sumo Diaper is a fitted cloth diaper that consists of a waterproof cover and absorbent inserts. The cover is sewn in such a way that a pocket is formed: this is where the absorbent pad is inserted to prevent slipping.

To further enhance the performance of this absorbent pad, the Sumo team went in search of a partner and found one in the renowned viscose special fibre manufacturer Kelheim Fibres. “Kelheim Fibres’ specialty fibres are a perfect fit for us. Like all the fabrics we have developed for Sumo diapers, the fibres in the insert developed with Kelheim are based on cellulose and are biodegradable. They are as good to baby’s skin as they are to the environment, and – thanks to their targeted functionalisation – they outperform other cellulosic fibres, as well as synthetic fibres,” says designer Luisa Kahlfeldt.

Beyond that, Kelheim Fibres brings decades of experience from the hygiene sector, especially for sensitive applications where high absorbency is required (such as tampons), and has made a name for itself in the industry as an innovation pioneer.

Together, Sumo and Kelheim Fibres have developed a high-performance absorbent pad that uses no fossil materials.

The basis for the innovative design form Kelheim’s functionalised specialty viscose fibres with adapted cross-sections. Needle-punched / thermobonded nonwovens with a blend of specialty viscose and PLA bicomponent fibres were chosen to ensure the product’s washability. PLA stands for polylactic acid made from natural and renewable raw materials. By combining nonwovens, usually found mainly in the single-use sector, with reusable products, Sumo and Kelheim Fibres have chosen a completely new approach.

Inside the pad, the speciality fibres from Kelheim score with their special properties: In the distribution layer (ADL), the trilobal cross-section of the Galaxy® fibre forms capillary channels that enable efficient and optimized liquid distribution and thus optimum use of the capacity of the absorbent core, offering the lowest rewet values.

In the absorbent core, the segmented hollow fibre Bramante stores liquid not only between but also inside the fibre. The liquid remains there even when pressure is applied to the construction, providing excellent rewet values. Bramante can absorb up to 260% of its own weight in liquid (cotton only achieves values of around 50% here).

The innovative nonwoven construction with the speciality fibres from Kelheim performs significantly better in tests in terms of air permeability, liquid absorption and rewetting than commercially available solutions made of synthetic fibres or cotton in knitted structures, and has earned Sumo diapers a place among the finalists for the IDEA® Long-Life Product Achievement Award.

Dr. Marina Crnoja-Cosic, Director New Business Development at Kelheim Fibres, said, “Working with Sumo is inspiring and professional in equal measure. We share a passion for driving the transformation to a bio-based society with innovative solutions. The entire Kelheim Fibres project team, led by Innovation Manager Ilka Kaczmarek and Project Manager Dominik Mayer, is very proud that our fibres are now part of the Sumo diaper, offering young parents a sustainable product that meets their need for a comfortable, reliable and skin-friendly diaper solution for their babies.”

The launch is scheduled for the first of May.

For the second time in a row, the speciality viscose fibre manufacturer Kelheim Fibres was awarded a place on the podium at the Cellulose Fibre Innovation of the Year Awards. The concept for sustainable menstrual underwear made from Kelheim’s functionalised speciality fibres achieved third place. Kelheim Fibres thus emerges from the competition as the most innovative fibre manufacturer.

Natalie Wunder presented the promising concept from Kelheim at the International Conference on Cellulose Fibres and is pleased about the great interest and the placing: “We have been able to use our experience as a long-established supplier for the tampon industry to develop further sustainable solutions in the feminine hygiene sector, in this case reusable menstrual underwear. As an innovation pioneer, we are thus helping to break the taboos that surround the topic of menstruation. We offer women the choice between different environmentally friendly products which also offer high levels of performance – depending on what fits their lifestyle.”

For the next step, the commercialisation of the concept, Dr Marina Crnoja-Cosic, Director New Business Development at Kelheim Fibres, puts her trust in the proven open innovation approach: “We want to bring partners from the entire value chain together. By bringing in our joint expertise, we can significantly accelerate the path from idea to finished product in the market. At the same time, through open dialogue, we ensure that the concept works seamlessly from fibre through processing to the final product.”